Case Studies

Real-world motor repair success stories

Proven Results

See how we've helped industrial facilities minimize downtime and extend motor life

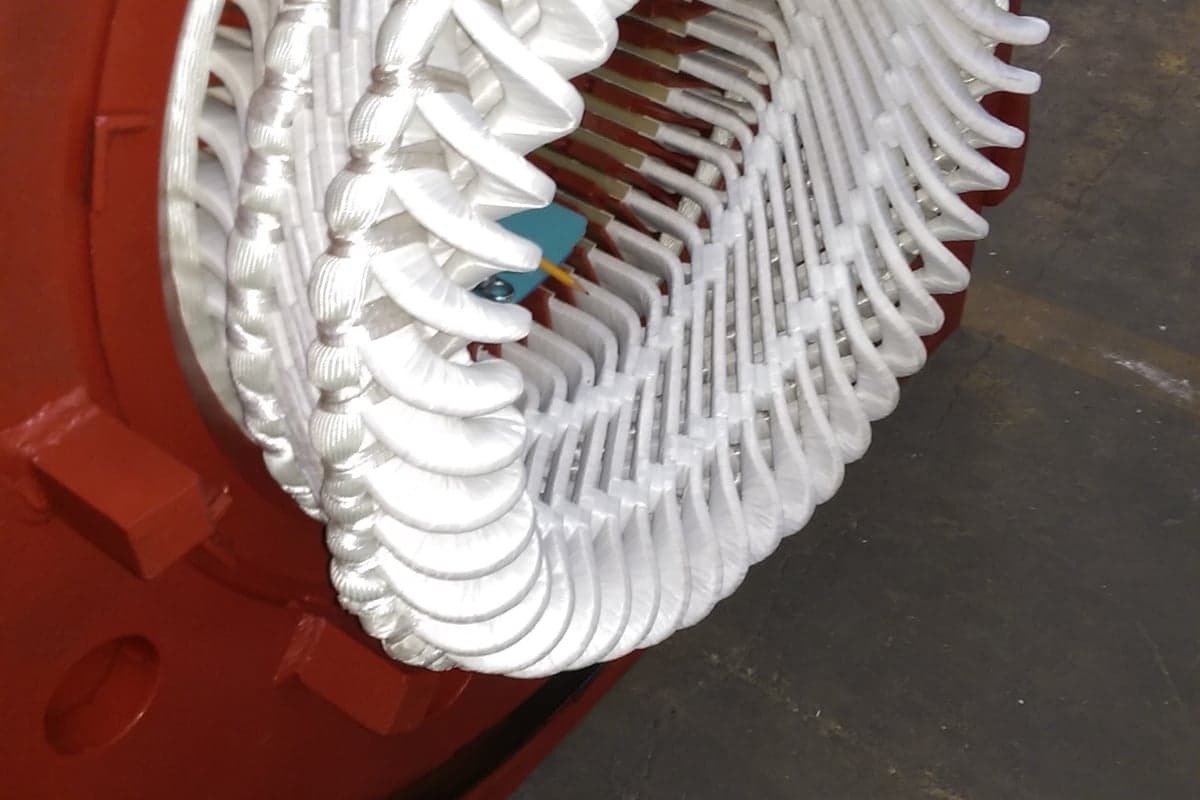

High-Voltage Motor Repair for Power Plant

Challenge:

A 5000 HP, 4160V synchronous motor failed during peak demand, causing production shutdown.

Solution:

Emergency repair service with 24/7 support. Complete stator rewinding, rotor repair, and comprehensive testing.

Results:

- Motor restored to full operation in 3 weeks

- Performance exceeded original specifications

- Zero downtime incidents since repair

AC Motor Rewinding for Manufacturing Line

Challenge:

Multiple 200 HP three-phase motors failing prematurely on production line, causing frequent downtime.

Solution:

Complete motor assessment, rewinding with improved insulation, and bearing upgrades.

Results:

- Extended motor life by 40%

- Reduced unplanned downtime by 60%

- Improved energy efficiency

DC Motor Armature Repair for Mining Equipment

Challenge:

DC motor armature failure in critical mining conveyor system requiring immediate repair.

Solution:

Complete armature rewinding, commutator repair, and field coil services with fast turnaround.

Results:

- Repair completed in 5 business days

- Motor performance restored to original specs

- No further issues after 2 years of operation

Servo Motor Encoder Calibration for CNC

Challenge:

Precision servo motors losing position accuracy, causing production defects.

Solution:

Servo motor repair, encoder replacement, and precision calibration for accurate positioning.

Results:

- Position accuracy restored to ±0.001mm

- Production defects eliminated

- Improved machining quality

Ready to See Similar Results?

Contact us to discuss your motor repair needs and see how we can help minimize downtime and extend motor life.

Get a Quote