Quality & Compliance

Commitment to excellence and regulatory compliance

Quality First Approach

Quality is not negotiable in industrial motor repair. Every motor that leaves our facility must meet or exceed original equipment manufacturer specifications. We maintain rigorous quality control processes at every step of the repair process.

Our quality assurance program includes comprehensive testing, detailed documentation, and continuous improvement. We use only high-quality materials and follow industry best practices for every repair.

Request Information

Standards & Compliance

We adhere to the highest industry standards and maintain compliance with key regulatory bodies

NEMA

National Electrical Manufacturers Association standards for motor design, performance, and efficiency

IEEE

Institute of Electrical and Electronics Engineers standards for testing, quality, and safety

EASA

Electrical Apparatus Service Association certified repair and rewinding practices

OSHA

Occupational Safety and Health Administration workplace safety and health compliance

NEMA Standards

We follow NEMA standards for motor design, performance, and efficiency. Our repairs maintain NEMA frame sizes, mounting dimensions, and performance characteristics.

- • NEMA MG 1 - Motors and Generators

- • Frame size compliance

- • Performance standards

- • Efficiency requirements

IEEE Standards

We follow IEEE standards for electrical testing, quality assurance, and safety. Our testing procedures meet IEEE requirements for motor evaluation.

- • IEEE 43 - Insulation Testing

- • IEEE 112 - Motor Testing

- • IEEE 115 - Synchronous Machine Testing

- • Quality assurance standards

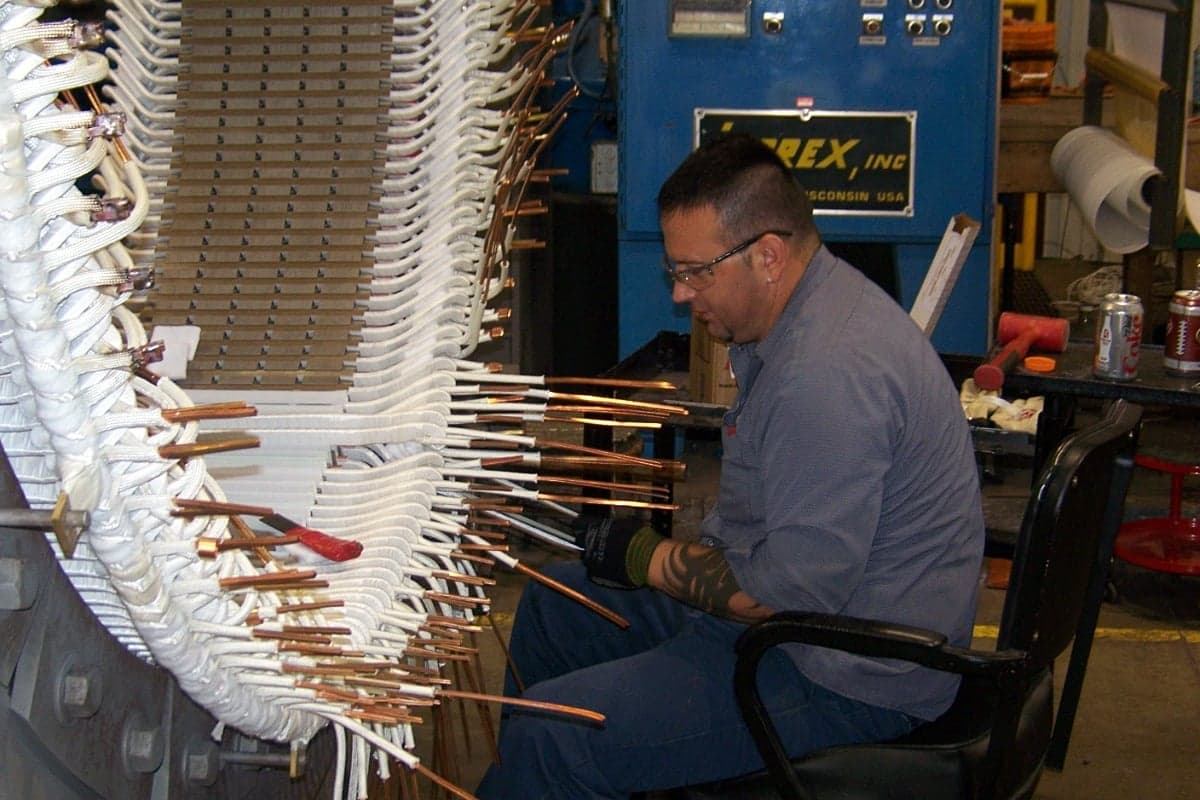

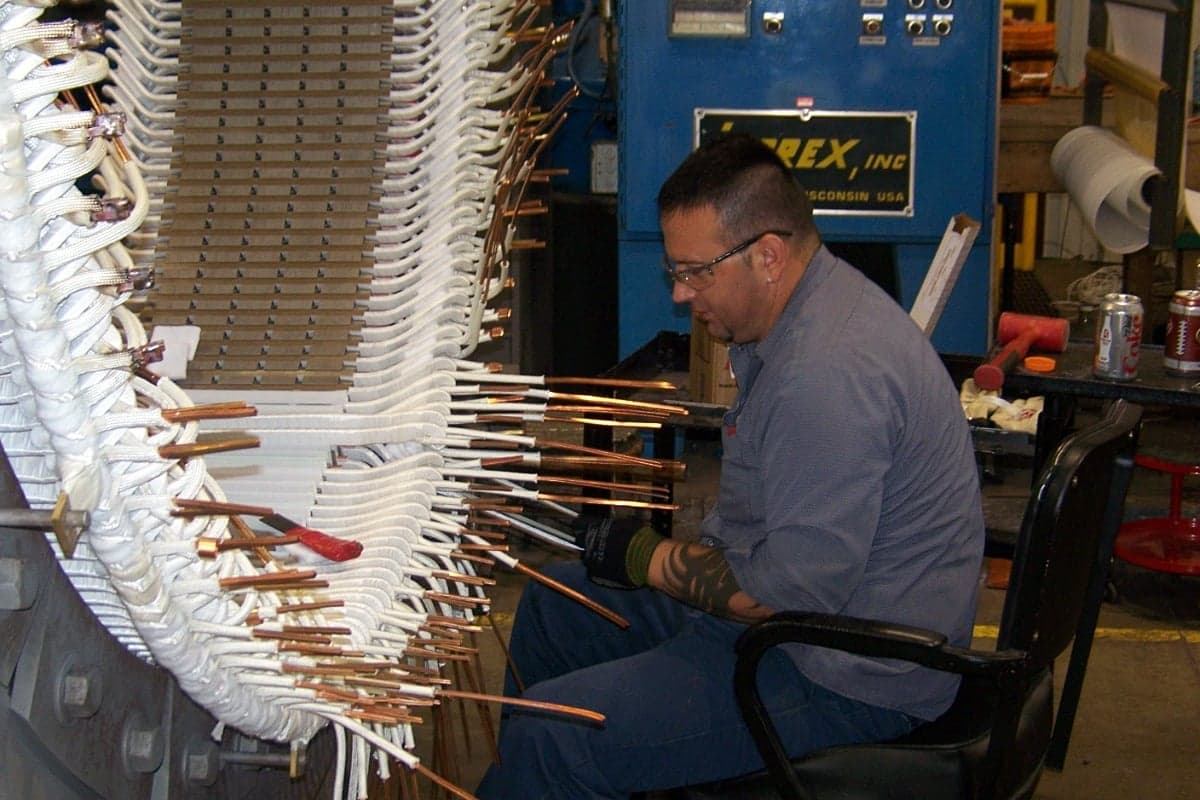

EASA Standards

We follow EASA best practices for motor repair and rewinding. Our technicians are trained in EASA-certified repair procedures.

- • EASA AR100 - Motor Repair Standards

- • Winding best practices

- • Testing procedures

- • Documentation requirements

OSHA Compliance

We maintain OSHA compliance for workplace safety and health. Our facility follows OSHA standards for electrical safety, personal protective equipment, and workplace safety.

- • Electrical safety standards

- • Personal protective equipment

- • Workplace safety protocols

- • Hazard communication

Quality Assurance Process

Comprehensive testing and quality control at every stage

Material Quality

We use only high-quality materials from trusted suppliers. All materials meet or exceed OEM specifications.

Process Control

Systematic processes ensure consistency and quality. Every repair follows documented procedures.

Testing & Verification

Comprehensive testing verifies performance and reliability. We provide detailed test reports with every repair.

Quality You Can Trust

Experience the difference that commitment to quality and compliance makes.

Contact Us